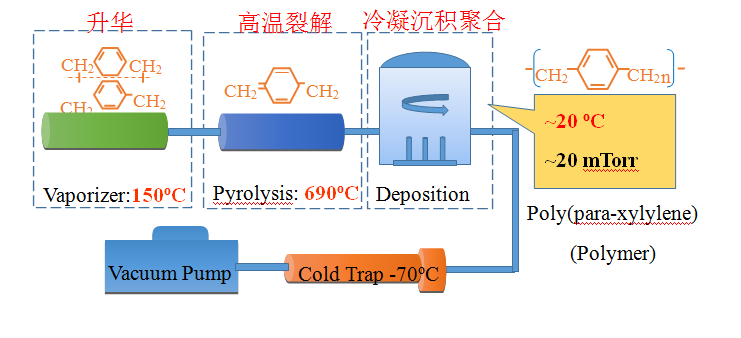

CVD is the most advanced thin film deposition technique that uses a process, wherein a chemical reaction takes place in a chamber and turns the reactant (gas)to a solid product which deposes on the target surface.

info@sunlight-eco.com

Unit 507, Enterprise Place,5 West Science

Park Avenue, Sha Tin, Hong Kong

Advantage

- Characterizing excellent coverage, far superior to coating with epoxy, urethane or silicone.

- Excellent chemical properties, can resolve problems caused by corrosion by acids or alkaline.

- Colorless, and highly transparent, the original appearance and property of the target objects are not affected.

- Can prevent surface particles from coming off the product.

- Completely weather proof, moisture-proof, rust-proof and weathering mitigated.

- Organic solvent resistant (not resolved in any common solvents). Mildew resistant, and antimicrobial.

- Low permeability to gases, high shielding effect.

- Excellent temperature stability (±200℃).

- Excellent temperature stability (-200℃~+400℃) for AF4.

- Mildew resistant, and antimicrobial.

- Low friction coefficient.

- High insulation resistance and high voltage with standability.

Application range

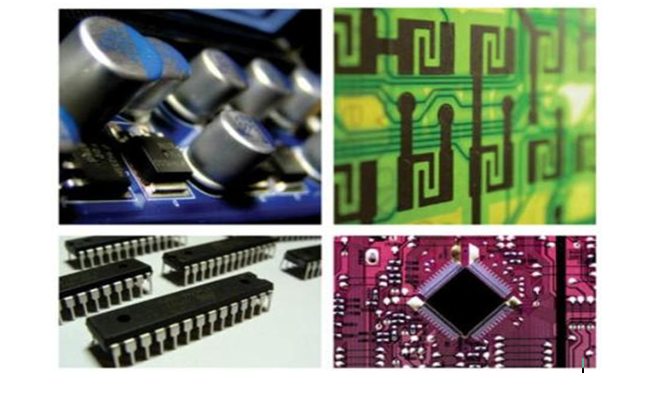

1. Semi-conductor manufacturing

Molecular coating protects the PCB from moist the service life.

Meet the requirements of electronic equipment or sensing components in a strict standard environment, such as semiconductor processing, MEMS and other high-tech industries.

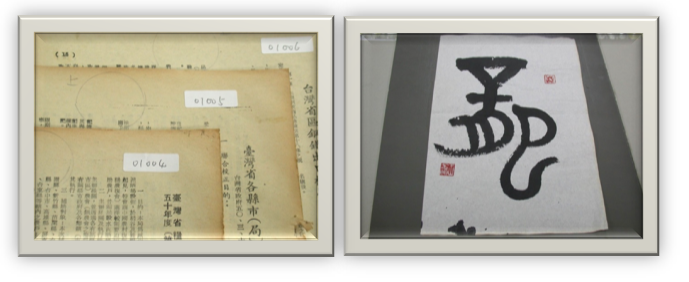

2. Protection of important documents and antiques

Molecular coating can be painted on any shape of an object without damaging the appearance of the artifacts.

Water-proof, anti-rust, antibacterial and mothproof.

3.The upgrading of traditional industries

Molecular coating can be painted on any shape of an object without damaging the appearance of the artifacts.

Water-proof, anti-rust, antibacterial and mothproof.